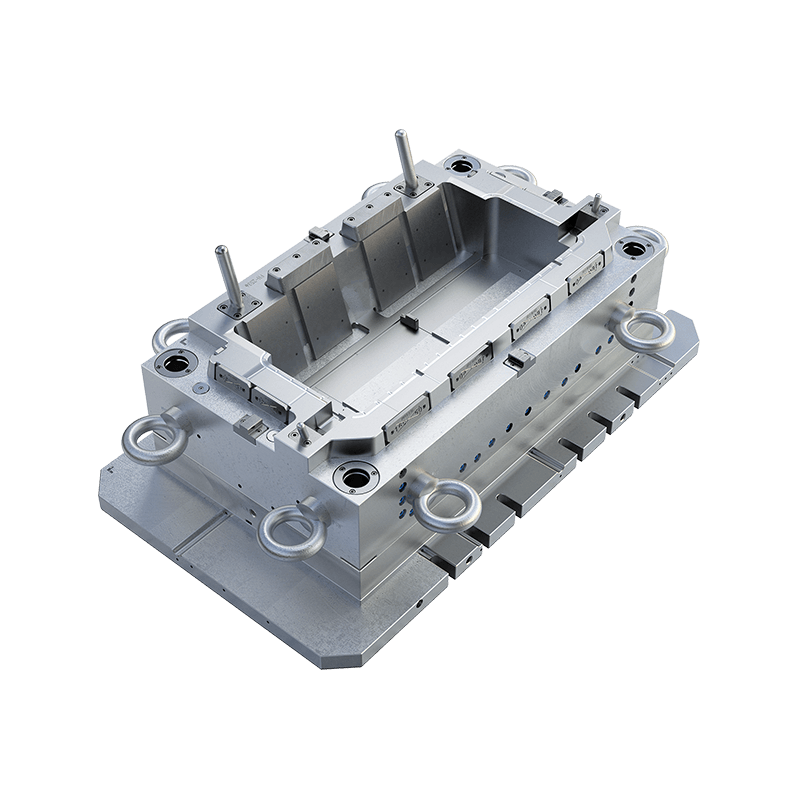

FHM mould is plastic injection mould manufacturer ,which is located in huangyan, taizhou city,china. We are specialized in making different type of air conditoning injection mould, air cooler mould, washing machine moulds ,blender mould.

FHM mould is one of professional plastic moulded home appliances mould manufacturer.We offer different size,shape and design of washing machine mould according customer's requirements. FHM mould have experience on AC mould .air cooler mould, washing machine moulds ,blender mould.

There are experienced team special for home appliance mould the complete solution of high precision home appliance moulds can be offered according to customers' ideas, from mouldflow analysis, product design optimization, mould design improvement and plastic parts production, which would ensure the smooth surface of home appliance, and perfect assembling.

We are still developing our technology in the home appliance molding to offer the better and better solutions for the home appliance moulds.

Plastic fan mould Industry Knowledge Extension

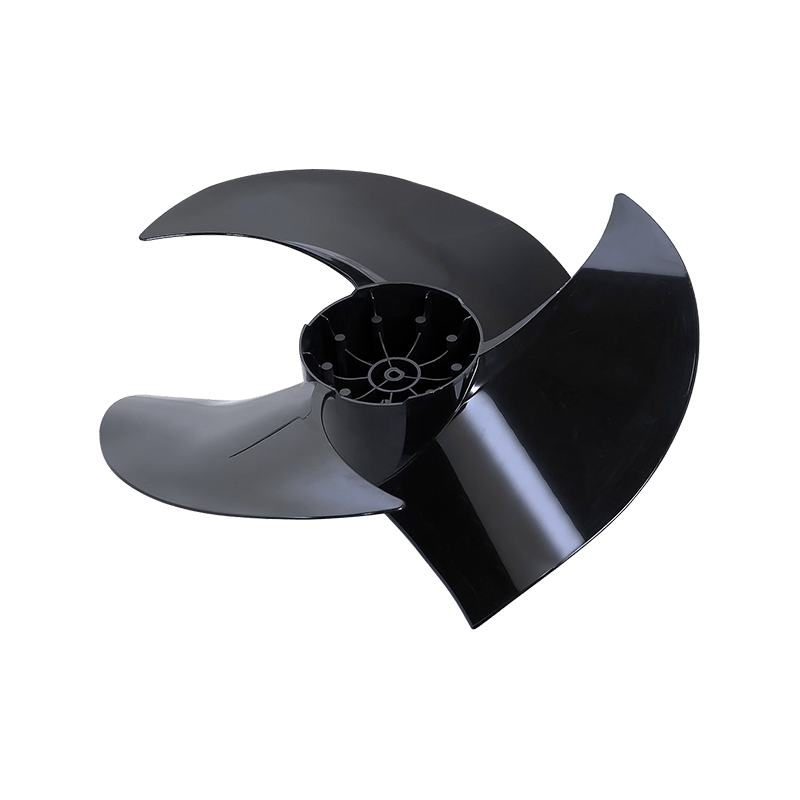

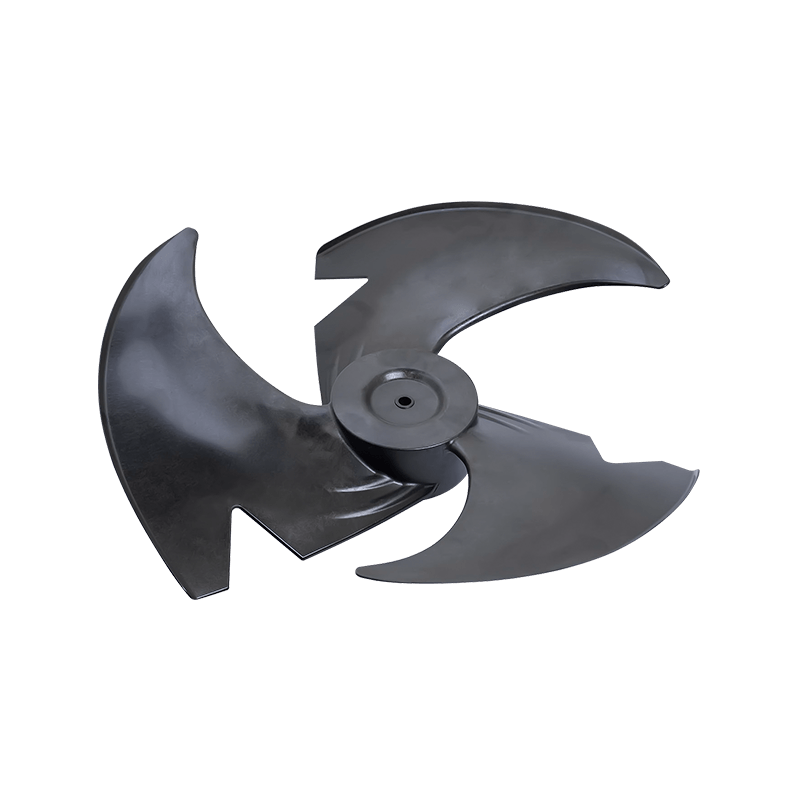

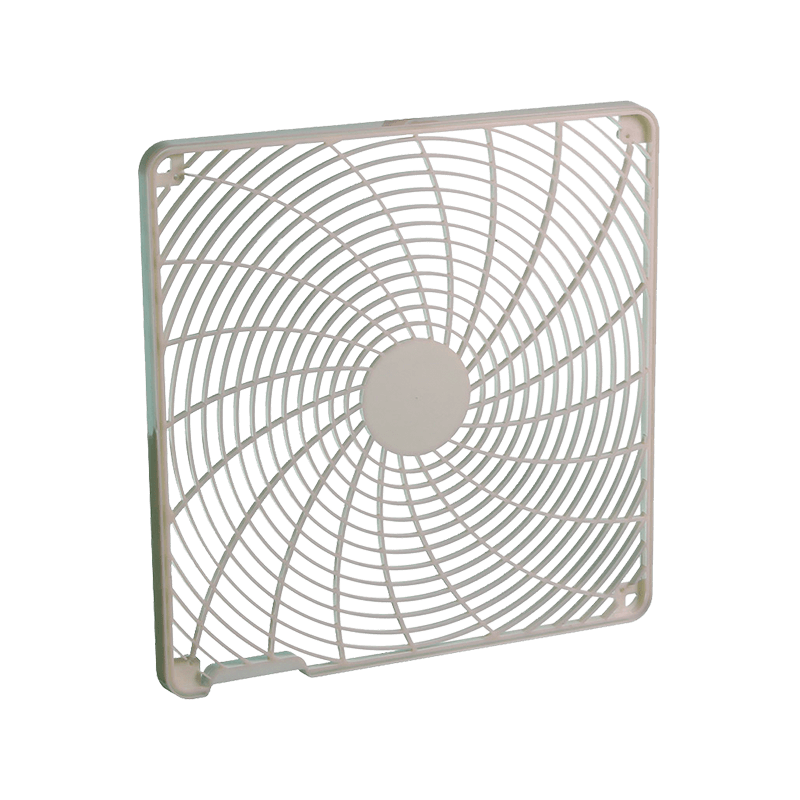

The Plastic Fan Mould is a vital component in the home appliance mold industry, designed to create high-quality plastic parts such as fan blades. An intricately designed Plastic Fan Mould ensures the manufacturing of fan blades that are not only aesthetic but also durable and efficient in their function. When speaking of the Window Fan Blade Mould, this refers to a specific type of mould designed for creating blades used in window fans, a common household appliance designed to provide ventilation and air circulation.

The Window Fan Blade Mould is designed with several key features in mind. Its aerodynamic shape suggests that it has been optimized for air movement, pushing air effectively when rotated at high speeds. This efficiency is paramount for window fans that are expected to offer comfort in indoor spaces. The Window Fan Blade Mould must produce blades with precise angles and curves to maximize air displacement while minimizing noise—a critical factor for residential environments.

Moreover, the color of the fan blade, which is typically the default color of the plastic used, can be customized based on the requirements of the brand or the design aspects of the specific model of the fan. Here the color is a standard black, indicating that the material might be ABS or a similarly robust plastic. The choice of material is key, as a Plastic Fan Mould must be compatible with a variety of plastics to accommodate different product specifications and requirements.

Another consideration in the design of this fan blade, possibly arising from a Plastic Fan Mould, is the integration of mounting points. The central hub appears to a precise geometric shape, intended for a snug and secure fit onto the motor shaft of the fan. This aspect of the design is essential for the safe and reliable operation of the fan, and therefore, a high degree of precision in the Plastic Fan Mould is required for the correct fitting.

When talking about the industrial process, the Plastic Fan Mould plays a pivotal role. The mould itself must be engineered to exact specifications and is commonly crafted from metals like steel or aluminum to withstand the high pressures and temperatures involved in the plastic injection moulding process. The surface of the blade highlights a smooth finish, indicative of a high-quality Plastic Fan Mould that ensures the molten plastic fills the mould evenly without creating defects such as warping, sink marks, or flash.

Considering the broader implications of using a Plastic Fan Mould, sustainability is a topic that cannot be neglected. Advances in the home appliance mould industry have led to the creation of reusable Plastic Fan Moulds that reduce waste and can be used to produce fan blades from recycled plastics, lowering the environmental impact.

In contrast, the specifics of a Window Fan Blade Mould speak to the need for customized tooling to produce fan blades suitable for the unique environment in which a window fan operates. These fans are often exposed to external elements; thus, the Window Fan Blade Mould must facilitate the production of blades that can withstand sunlight, changes in temperature, and potential moisture from rain.

When it comes to installation and, the output of the Plastic Fan Mould must align with consumer needs. The customer may seek blades that are easy to install, clean, and replace if necessary. In this context, a high-quality Window Fan Blade Mould will allow for the production of fan blades that are user-friendly, perhaps featuring snap-on or modular designs that cater to the DIY market.

Lastly, the manufacturing process employing a Plastic Fan Mould, including a Window Fan Blade Mould, must adhere to various industry standards and safety regulations. It is of utmost importance that products like the fan blade shown comply with these standards to ensure the safety and satisfaction of the end-user.

In the continuously evolving world of home appliances, the Plastic Fan Mould and the Window Fan Blade Mould serve as critical tools in the production chain. These types of moulds represent high investment in precision engineering and design to produce components that meet the diverse needs of consumers and manufacturers alike.