FHM mould is plastic injection mould manufacturer ,which is located in huangyan, taizhou city,china. We are specialized in making different type of air conditoning injection mould, air cooler mould, washing machine moulds ,blender mould.

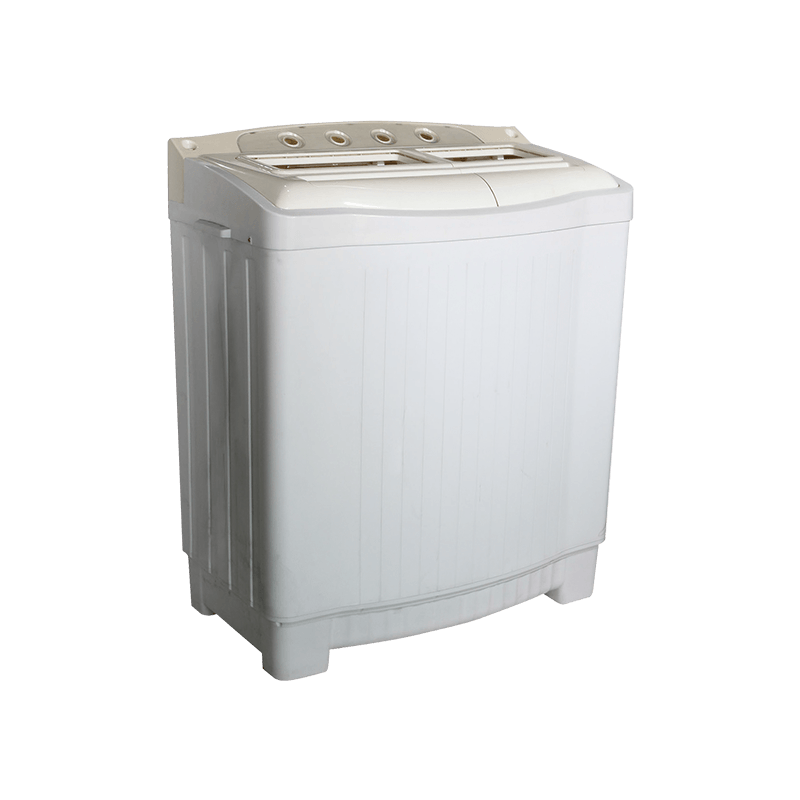

FHM mould is one of professional plastic moulded home appliances mould manufacturer.We offer different size,shape and design of washing machine mould according customer's requirements. FHM mould have experience on AC mould .air cooler mould, washing machine moulds ,blender mould.

There are experienced team special for home appliance mould the complete solution of high precision home appliance moulds can be offered according to customers' ideas, from mouldflow analysis, product design optimization, mould design improvement and plastic parts production, which would ensure the smooth surface of home appliance, and perfect assembling.

We are still developing our technology in the home appliance molding to offer the better and better solutions for the home appliance moulds.

Plastic washing machine mould Industry Knowledge Extension

Advantages of Plastic Washing Machine Mould:

Durable Materials Selection:

The Plastic Washing Machine Mould is crafted from durable materials carefully selected for their resilience to water, temperature variations, and wear. This ensures the longevity and robustness of the moulded components, contributing to the overall durability of the washing machine.

Customization Flexibility:

Recognizing the diverse preferences of consumers, the Plastic Washing Machine Mould offers customization options. Manufacturers can tailor the mould to specific design requirements, ensuring that the washing machine aligns with varying consumer aesthetics.

Ease of Maintenance:

The mould's design prioritizes user convenience. The resulting washing machine components are easy to clean and maintain, promoting a hassle-free experience for end-users. This aligns with our commitment to providing solutions that enhance the overall user experience.

Applications of Plastic Washing Machine Mould:

Our Plastic Washing Machine Mould finds versatile applications across the home appliance industry, contributing to the production of washing machines tailored for different needs.

Residential Spaces:

The Plastic Washing Machine Mould is integral in creating washing machines for residential use. Its design ensures optimal performance and durability, meeting the demands of everyday laundry needs in households.

Commercial Laundry Services:

The robustness of the Plastic Washing Machine Mould makes it suitable for commercial laundry services. The moulded components withstand the rigors of frequent use, delivering consistent and reliable performance in high-demand settings.

Industrial Applications:

In industrial settings where large-scale washing machines are required, the Plastic Washing Machine Mould excels. Its durability, coupled with efficient manufacturing processes, makes it a preferred choice for industrial washing machine production.

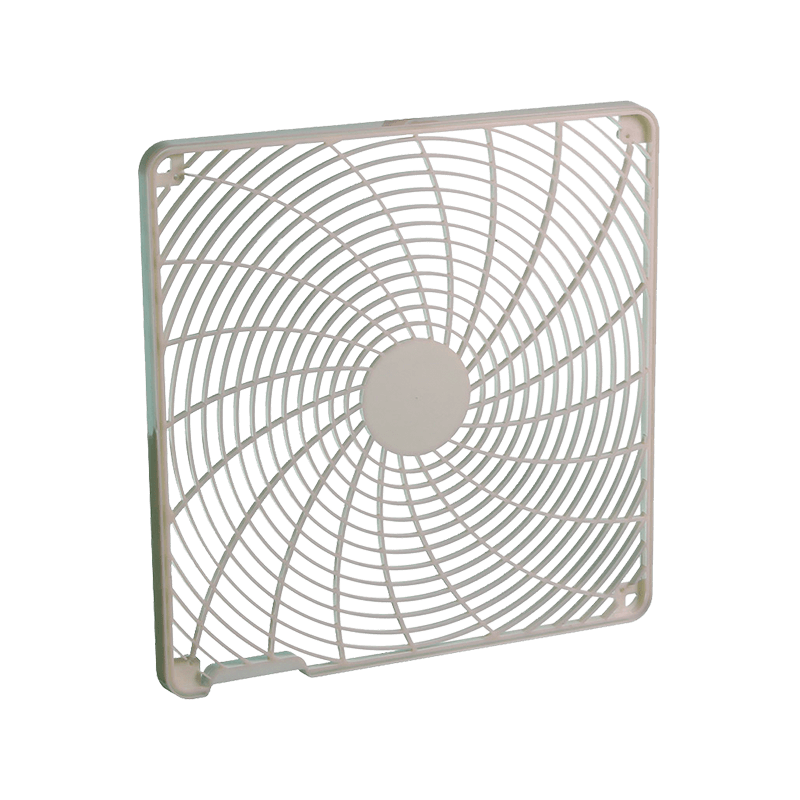

Pulsator Washing Machine Mould: Enhanced Cleaning Dynamics

The Pulsator Washing Machine Mould is a key component that influences the washing machine's cleaning performance. Let's explore the distinctive features that set this mould apart.

Dynamic Pulsating Action:

The Pulsator Washing Machine Mould is designed to facilitate a dynamic pulsating action within the washing machine. This unique feature enhances the cleaning efficiency by creating a powerful water flow, ensuring thorough washing of clothes with minimal tangling.

Optimized Water Distribution:

Precision in mould design allows for optimized water distribution during the washing cycle. The Pulsator Washing Machine Mould ensures that water reaches all areas of the drum, promoting effective detergent dispersion and superior cleaning results.

Gentle on Fabrics:

While delivering powerful cleaning, the Pulsator Washing Machine Mould is engineered to be gentle on fabrics. Its design minimizes friction and abrasion, preserving the quality and longevity of clothes even after repeated wash cycles.

Washing Machine Shell Mould: Aesthetic and Protective Design

The Washing Machine Shell Mould contributes not only to the aesthetics of the washing machine but also to its protective functionality.

Sleek and Modern Design:

Crafted with a sleek and modern design, the Washing Machine Shell Mould enhances the visual appeal of the washing machine. It adds a touch of sophistication, making the appliance an attractive addition to any laundry space.

Durability and Protection:

The materials used in the Washing Machine Shell Mould prioritize durability and protection. The resulting shell is robust, providing a protective layer around the internal components, safeguarding the washing machine from external impacts and environmental factors.

Variety of Finishes:

Recognizing the importance of customization, the Washing Machine Shell Mould offers a variety of finishes. Manufacturers can choose from different colors and textures, allowing them to tailor the washing machine's appearance to suit diverse consumer preferences.

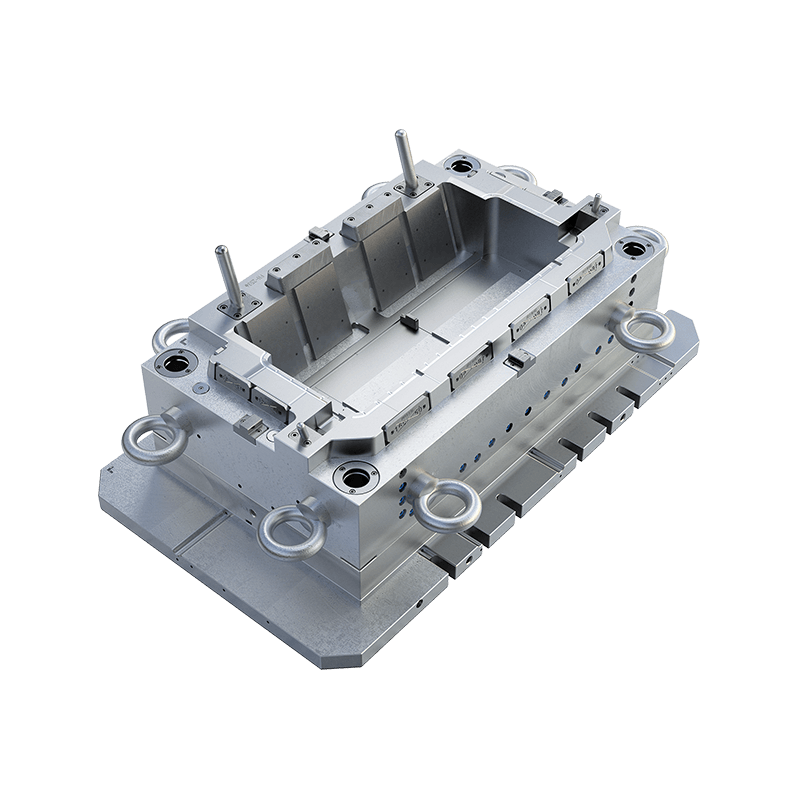

Manufacturing Process of Plastic Washing Machine Mould:

Material Preparation:

The manufacturing process begins with the preparation of high-quality plastic materials selected for their durability and suitability for home appliance use.

Mould Design and Creation:

Our expert designers create precise mould designs, considering factors such as component dimensions, water flow dynamics, and aesthetic details. The mould is then meticulously crafted, ensuring accuracy in every detail.

Injection Moulding:

The injection moulding process is employed to produce components from the Plastic Washing Machine Mould. This highly efficient process allows for rapid and cost-effective manufacturing while maintaining the integrity of the moulded parts.

Quality Control:

Rigorous quality control measures are implemented throughout the production process. Each component is thoroughly inspected to ensure adherence to design specifications, durability, and overall quality.