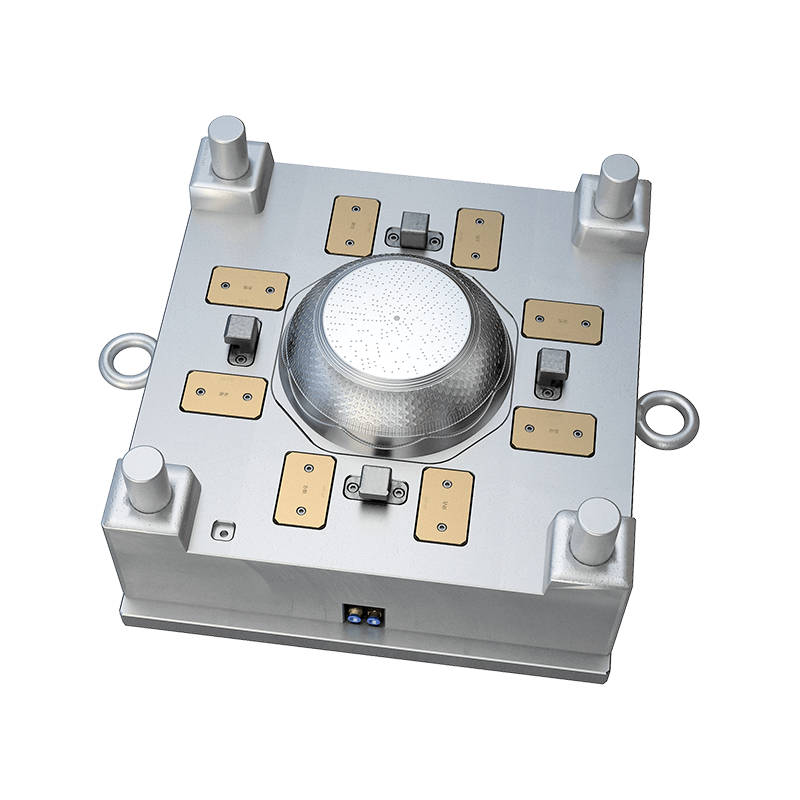

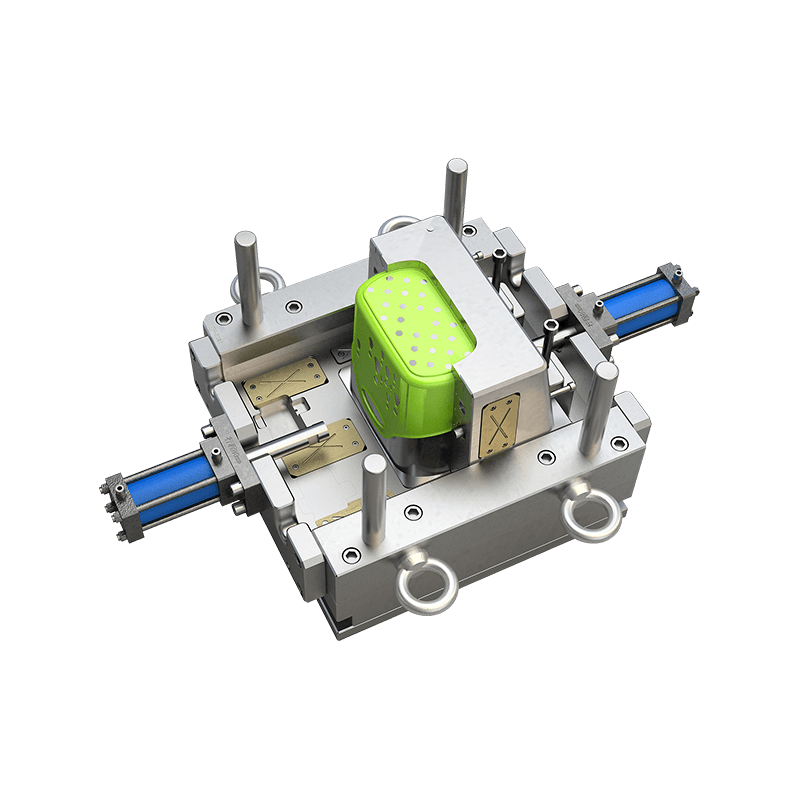

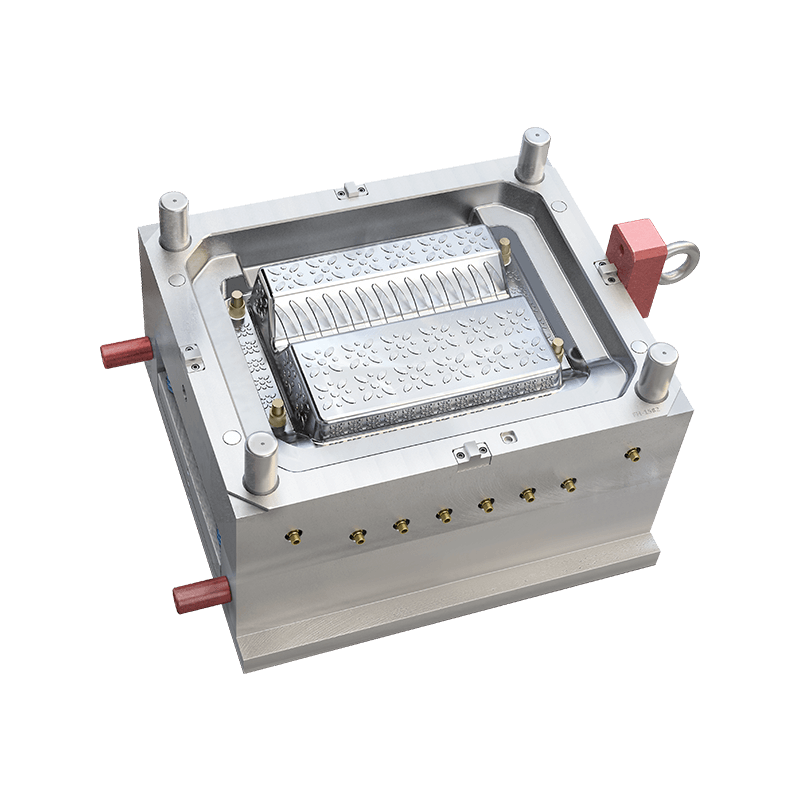

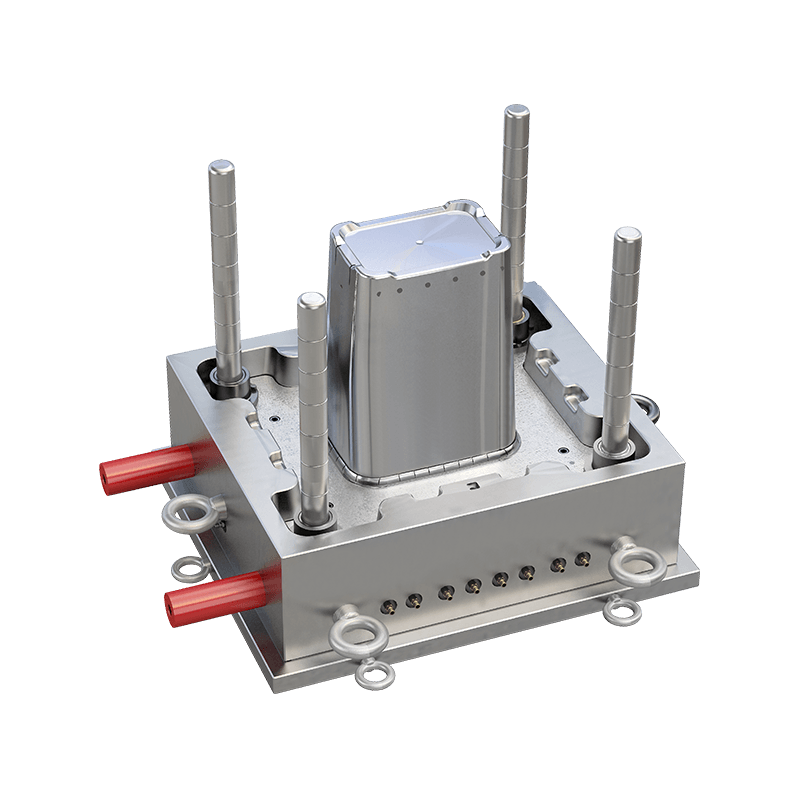

FHM mould is plastic injection mould manufacturer, which is located in huangyan, taizhou city, china. We are specialized in making different type of houseward mould. plastic bucket mould. laundry mould. basket mould. basin bin mould, storage box mould.

FHM mould is one of professional plastic moulded houseward mould manufacturer. We offer different size, shape and design of houseward mould according customer's requirements. FHM mould have experience plastic bucket mould.laundry mould. basket mould. basin bin mould, storage box mould.

There are experienced team special for houseward mould the complete solution of high precision houseward moulds can be offered according to customers' ideas, from mouldflow analysis, product design optimization, mould design improvement and plastic parts production, which would ensure the smooth surface of houseward mould.

We are still developing our technology in the houseward molding to offer the better and better solutions for the houseward moulds.

Plastic bucket mould Industry Knowledge Extension

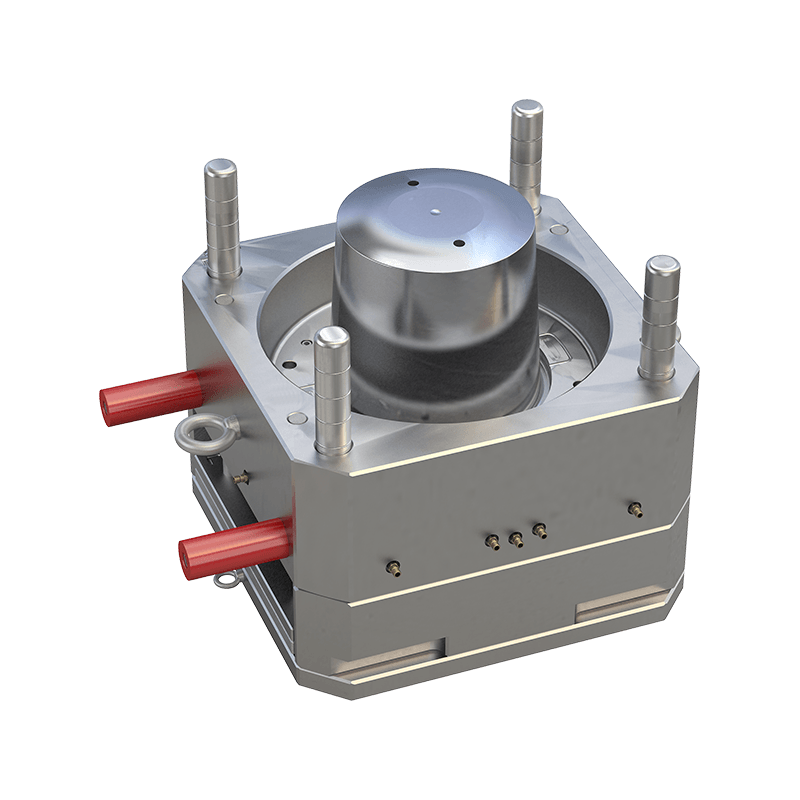

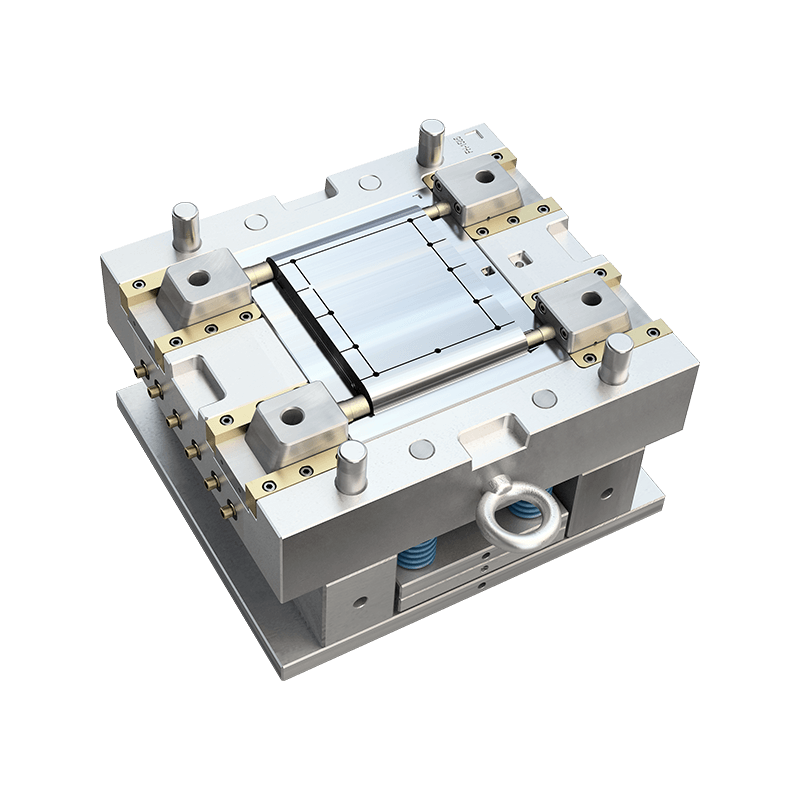

Precision Engineering for Plastic Round Bucket Mould:

Our Plastic Round Bucket Mould sets the standard for versatile and reliable bucket production. The manufacturing process begins with meticulous design, leveraging advanced technology to create a mould that seamlessly transforms raw materials into perfectly rounded buckets. The precision tooling phase ensures consistent quality and uniformity, while innovative cooling solutions optimize production cycles, enhancing efficiency without compromising on durability.

Durability and Structural Integrity:

Crafted from high-quality materials, our Plastic Round Bucket Mould guarantees buckets that are not only structurally sound but also resistant to wear and tear. The robust design ensures that these round buckets are suitable for a wide range of applications, from storing liquids to transporting goods with ease.

Customization Possibilities:

Our commitment to versatility shines through in the customization options available with the Plastic Round Bucket Mould. From varying sizes to color options, manufacturers can tailor the buckets to meet specific requirements. This adaptability ensures that the end products cater to diverse industries and applications.

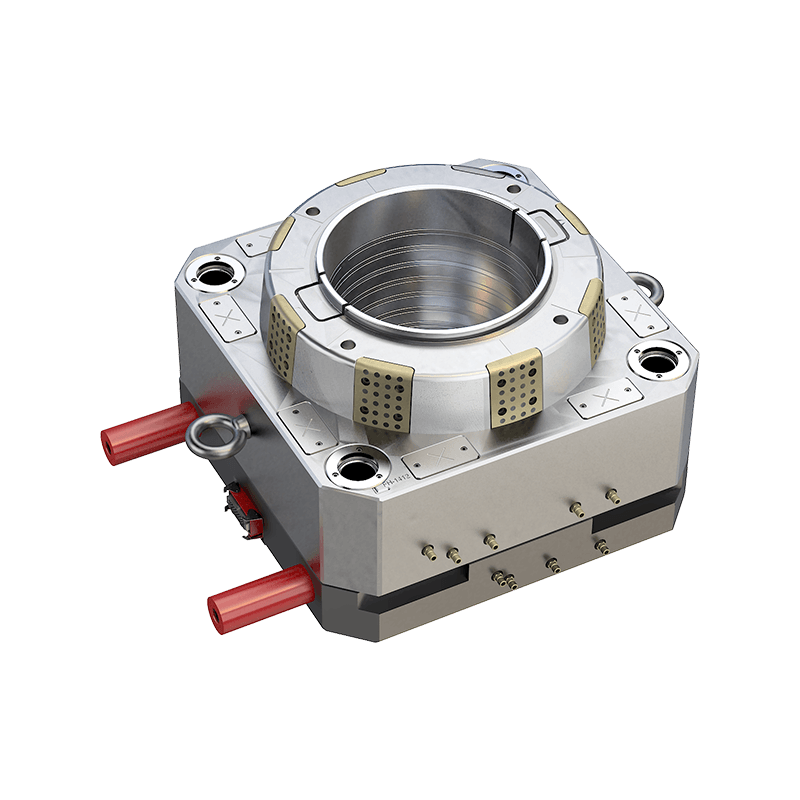

Innovation in Plastic Paint Bucket Mould:

The Plastic Paint Bucket Mould is a testament to our dedication to meeting the unique demands of the paint industry. Precision engineering is complemented by features that specifically address the challenges posed by paint storage and transportation.

Seal-Tight Design:

The mould is designed to create paint buckets with a seal-tight construction, preventing leaks and preserving the integrity of the paint. This feature ensures that paint remains fresh and ready for application, even during extended storage periods.

Easy Handling and Pouring:

Ergonomic handles and spouts are incorporated into the Plastic Paint Bucket Mould, facilitating easy handling and controlled pouring. These design elements enhance the user experience for both professionals and DIY enthusiasts, making the transportation and application of paint more convenient.

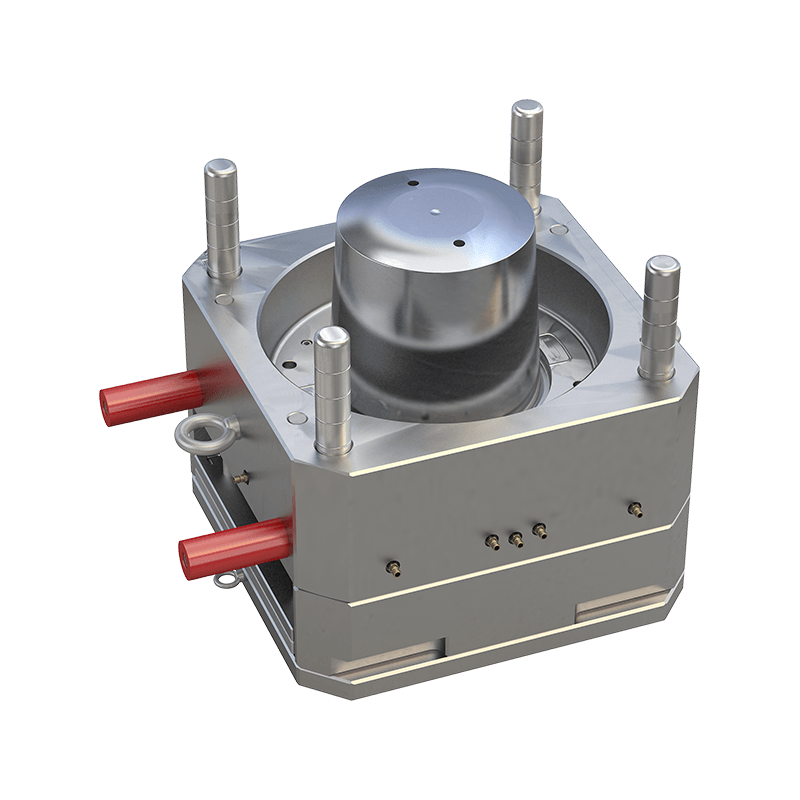

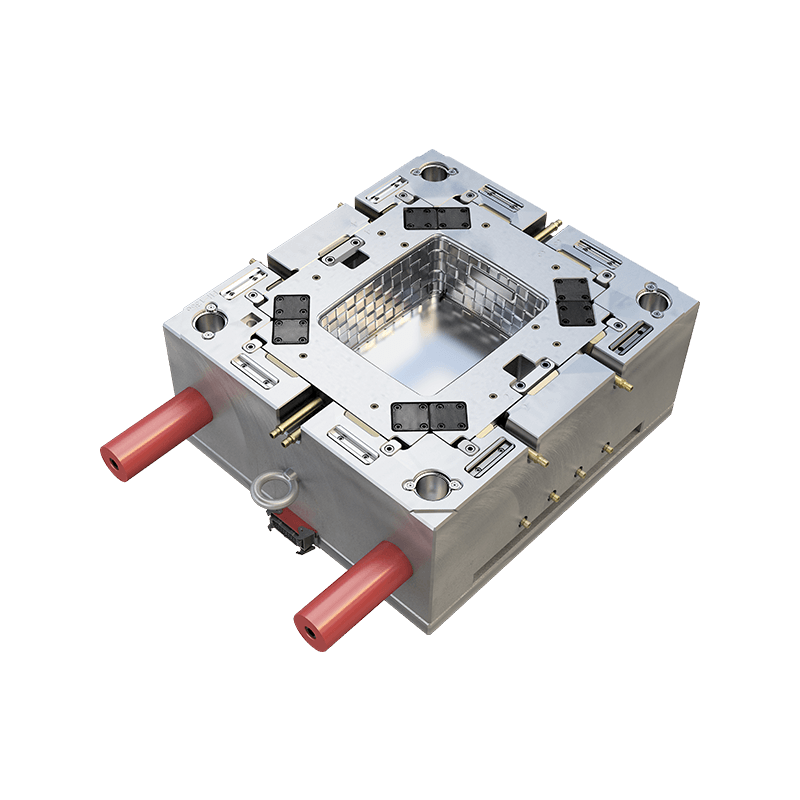

Injection Water Bucket Mould: Revolutionizing Water Storage:

Our Injection Water Bucket Mould takes water storage solutions to new heights with a focus on durability and efficiency.

Reinforced Structure for Heavy Loads:

The Injection Water Bucket Mould produces buckets with a reinforced structure, making them ideal for carrying and storing heavy loads of water. This design feature ensures that the buckets maintain their structural integrity even under challenging conditions.

Efficient Injection Molding Process:

The mould incorporates an efficient injection molding process, optimizing the production of water buckets. This results in shorter cycle times, reducing manufacturing costs and allowing for increased production volumes to meet high demand.

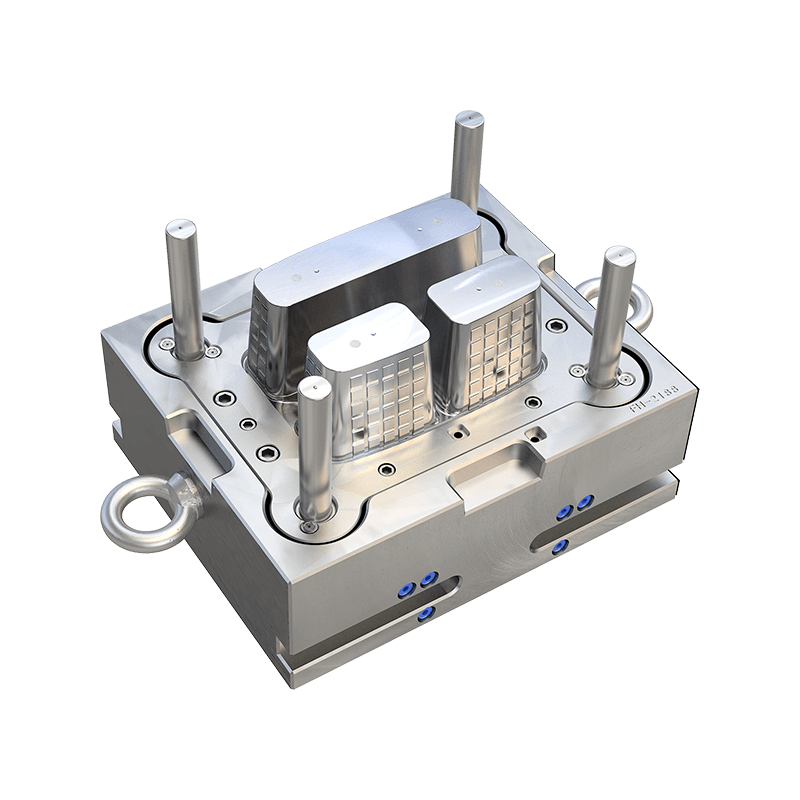

Manufacturing Excellence:

Advanced Tooling Technology:

Precision tooling is at the core of our manufacturing process. Cutting-edge technology is employed to create molds that guarantee the accuracy and consistency required for the production of high-quality plastic buckets.

Innovative Cooling Solutions:

Our moulds are equipped with innovative cooling solutions, a critical aspect of the manufacturing process. This not only accelerates production cycles but also enhances the overall quality of the moulded buckets, ensuring uniform cooling for optimal structural integrity.

Quality Control Measures:

Rigorous quality control measures are implemented at every stage, from material inspection to the final product. Our skilled professionals meticulously ensure that each Plastic Round Bucket, Plastic Paint Bucket, and Injection Water Bucket meets or exceeds industry standards.

In conclusion, our Plastic Round Bucket Mould, Plastic Paint Bucket Mould, and Injection Water Bucket Mould exemplify the pinnacle of plastic mould manufacturing. From precision engineering and durability to innovative features tailored to industry-specific needs, our moulds redefine the standards of bucket production. Elevate your products with our precision-crafted moulds – where innovation meets reliability, and versatility meets functionality.